Your Guide to the

Alle-Kiski Valley

and the Greater

Pittsburgh Area

Saturday

August 23, 2025

Home

Go Outside

History

Diversion

Back Issues

|

History - Industry - PPG Tarentum

|

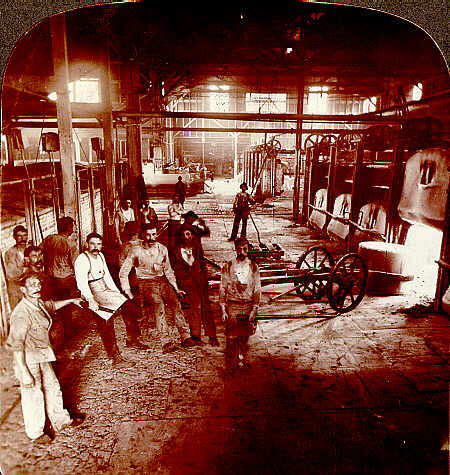

Drawing a Pot of Liquid

Glass from the Furnace

This is one of the furnace rooms of the Pittsburgh Plate Glass Co., at Tarentum, Pennsylvania.

The factory employs 600 men and runs day and night. Natural gas is used here for fuel

and you can see what a fearful glow comes from that furnace at the right where the

front has been opened. If you were as near as those men you would find the heat as

fierce as the glare of light.

That huge pot, which has just been dragged out of the furnace in those gigantic

tongs on wheels, had been in the fearful heat of the furnace some fifteen hours.

Before it was drawn out its contents were tested by thrusting in long iron rods

through a hole in the furnace door, as a cook tests boiling syrup; when its

condition was judged to be just right, the furnace drafts were closed to cool

off the fires. Then the doors were opened and the pot drawn out as you see it

now. That long iron bar held by the man in the middle of the room is a lever

for starting or stopping the wheels that move the tongs.

From this room the pot of fiery liquid stuff will be transferred to a truck and

taken to the casting-table in an adjoining room. An electric crane will then lift

the pot and pour its contents steadily over the surface of the casting table, an

immense steel roller following promptly over the horizontal mass of glass,

reducing it to an absolutely uniform level and to such thickness as may be desired.

After that, the huge sheet of glass has to go back to another furnace to be tempered;

then it is cut into required sizes and its surface ground and polished into plate-glass

perfection.

Next - Casting and Rolling

Sheets of Plate Glass

Previous - Modeling Clay Pots

for Molten Glass

Return - PPG Tarentum

|

|