Your Guide to the

Alle-Kiski Valley

and the Greater

Pittsburgh Area

Saturday

August 23, 2025

Home

Go Outside

History

Diversion

Back Issues

|

History - Industry - PPG Tarentum

|

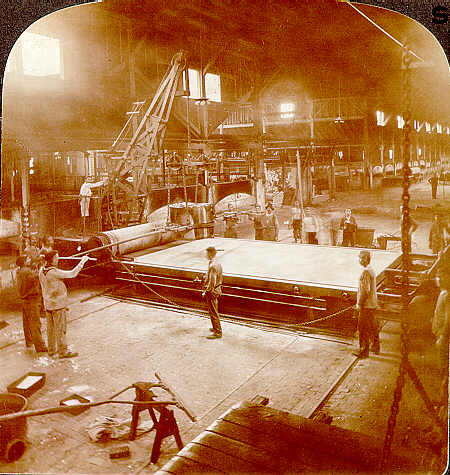

Casting and Rolling

Sheets of Plate Glass

Here we see one of the most interesting processes in the manufacture of glass. That huge

clay pot, poised above the casting-table, has just come from the furnace and contains

the fluid glass. The man on the platform of the electric cranes will release the levers

in such a way that the pot will be tapped to allow the glass to fall upon the mold.

That roller at the further end of the casting-table is then passed rapidly over the

mold to reduce the glass to a uniform thickness.

The mold will then go through a

series of furnaces called a "lehr." This "lehr" is generally about 200 feet long

and consists essentially of a continuous, covered, smooth, level bed of specially

prepared clay, which, beginning at the first furnace, heated to about the melting

point of glass, passes through five "stations," or furnaces, each in succession,

having a somewhat lower temperature.

The mold after resting in the first, or hottest

furnace, for a sufficient period, is slowly moved along through the four succeeding

stations, gradually losing its heat until the red "lehr" is reached, when it is

withdrawn. This entire process consumes only three hours, while in former days by

the old method it took three days. When it leaves the "lehr," the plate is thoroughly

set and ready to be taken off, ground and polished.

Next - Revolving Iron Disks

Grinding Surface

of Plate Glass

Previous - Drawing a Pot of Liquid

Glass from the Furnace

Return - PPG Tarentum

|

|