Your Guide to the

Alle-Kiski Valley

and the Greater

Pittsburgh Area

Saturday

August 23, 2025

Home

Go Outside

History

Diversion

Back Issues

|

History - Industry - PPG Tarentum

|

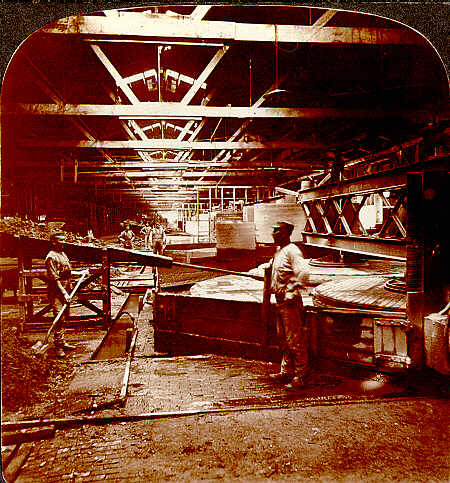

Revolving Iron Disks

Grinding Surface of Plate Glass

Here we see a plate of glass after it has been thoroughly set and is nearly ready for sale.

The machines now used for the grinding save a great deal of time. The improvement is

chiefly in the March transfer polishing table, which combines the advantages of reducing

the temperature of the glass while grinding, by circulating water below it, thus

permitting a much higher speed in the grinders, with a device for polishing the under

side of the plate, without the frequently disastrous operation of removing it from its

plaster bed and turning it over. This transfer table is also movable from grinder to

polisher, effecting in this way a considerable saving of time, while ensuring the

greatest security in handling.

There used to be many restrictions upon the output of the glass-workers by the

Glass-Workers' Union but immigrants, willing to work on an unlimited plan, forced

themselves into the trade, and this compelled the Union, for self-protection, to

remove the restrictions on its members. The increased production because of the

removal of the union limitations amounted, in one case, to 100 per cent, and the

increase of earnings to about fifteen per cent. A discriminating entrance fee,

so effective in other instances, is employed by the flint-glass workers to protect

themselves against an influx of cheap foreign workmen.

Next - Workmen Finishing

Plate Glass Windows

Previous - Casting and Rolling

Sheets of Plate Glass

Return - PPG Tarentum

|

|